On November 30, a high-performance carbon fiber project in Yungang District, Datong City, Shanxi Province, was completed and put into production. It has successfully achieved the localized mass production of 12K small-tow T1000-grade carbon fiber. The T1000-grade carbon fiber produced by the project has a single filament diameter of only 6 to 7 microns, less than 1/10 of a human hair, while its tensile strength exceeds 6400 MPa.

The realization of its localized mass production marks a crucial breakthrough in the large-scale mass production of domestic high-performance carbon fiber. Below is a detailed introduction from three aspects: core performance, production background, and application fields.

Excellent core performance

(1) Extremely lightweight with remarkable strength

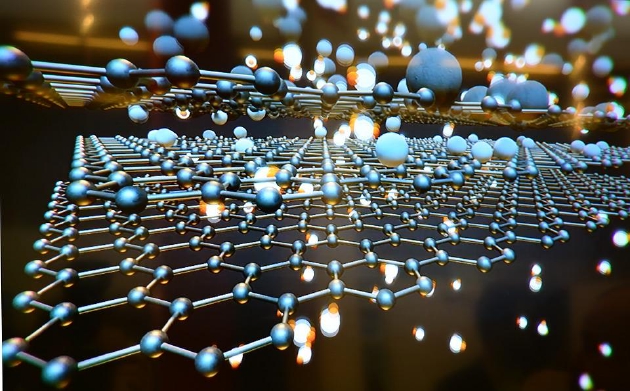

The single filament diameter of this carbon fiber is only 6 to 7 microns, less than 1/10 that of a human hair. Its density is merely 1/4 that of steel, while its strength exceeds 5 times that of steel, with a tensile strength breaking through 6400 MPa. For example, a 1-meter-long bundle of this grade of carbon fiber weighs only 0.5 grams but can bear a load of over 200 kilograms. This lightweight and high-strength characteristic endows it with significant advantages in scenarios requiring both weight reduction and structural strength.

(2) Outstanding comprehensive performance

It not only possesses superior mechanical properties but also integrates resistance to high and low temperatures, corrosion, and friction, along with good thermal and electrical conductivity. For instance, it can maintain structural stability and avoid significant performance degradation in extreme temperature environments or corrosive working conditions such as acid and alkali, making it suitable for various complex application scenarios.

Key production background

This project is jointly promoted by Huayang New Materials Technology Group Co., Ltd., Datong City, and the Institute of Coal Chemistry, Chinese Academy of Sciences. It specifically addresses the “bottleneck” issues in high-end key strategic materials. The first phase of the project, a 200-ton/year high-performance carbon fiber demonstration production line, started construction in June 2024, entered joint commissioning and testing in June 2025, and was finally put into production after more than a year of advancement. Its successful mass production has broken foreign technological monopolies, changed China’s reliance on imports for high-end carbon fiber, and filled the gap in this industrial field in Shanxi Province.

Wide-ranging strategic application fields

As a key strategic material, its applications cover multiple national priority areas. In the aerospace field, it can be used to manufacture aircraft components, helping reduce equipment weight and improve fuel efficiency. In the national defense and military industry field, it can provide reliable material support for high-end equipment. In fields such as rail transit and low-altitude economy, its lightweight and high-strength properties can help optimize the performance of related equipment. Additionally, its characteristics enable broad application potential in new energy vehicles, high-end equipment manufacturing, and other fields, which is of great significance for safeguarding national strategic material security.